Oil & Gas Industry Filtration Products

Fil-Trek has filtration and separation solutions to meet We are a leading provider of filtration solutions tailored to meet the unique challenges faced by the oil and gas sector. Our cutting-edge products and expertise ensure that your operations run smoothly, efficiently, and in compliance with industry standards. Fil-Trek has filtration and separation solutions to meet your increasing production and processing needs for upstream, midstream and downstream refining.your increasing production and processing needs for upstream, midstream and downstream refining.

Rental Options Available

Temporary Filtration Solutions

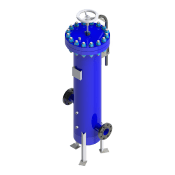

700H Series

Horizontal Multi-Round Cartridge Filter Housing

• ASME Code

• Multi-purpose

M Series Housings

High Pressure Single Cartridge Filter Housing

• ASME Code

• Up to 6150 PSIG

HT Series Housings

High Temperature Cartridge Filter Housing

• ASME Code

• ANSI Blind Flange Closure

LH Series

Horizontal Lined Cartridge Filter Housing

• ASME Code

• Ideal for corrosive applications

L Series Housings

Lined Cartridge Filter Housing

• ASME Code

• Ideal for corrosive applications

HF Series Housings

High Flow Cartridge Filter Housing

• ASME Code

• High flow rate applications

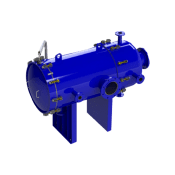

HFH Series

Horizontal High Flow Cartridge Filter Housings

• ASME Code

• High flow rate applications

UFH Series

Horizontal High Flow Cartridge Filter Housings

• ASME Code

• Complies with NSF/ANSI/CAN 61

• High flow rate applications

UF Series

High Flow Cartridge Filter Housing

• ASME Code

• Complies with NSF/ANSI/CAN 61

• High flow rate applications

GLH Series Filter Housing

Horizontal Multi-Round Cartridge Filter Housing

• ASME Code

• Complies with NSF/ANSI/CAN 61

• Multi-purpose

Temporary Strainers

Fabricated Temporary Strainers

• Cone

• Basket

• Plate

98 Series

Automatic Self-Cleaning Strainer

- ASME Code

- Screening 50 micron and up

- Flow Rates up to 20,000gpm

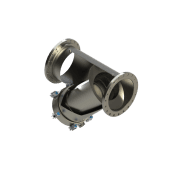

96 Series

Fabricated T Strainer

• Multiple Configurations

• NSF/ANSI 61

• ASME Code

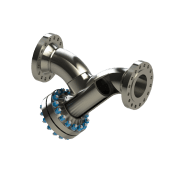

95 Series

Fabricated Y Strainer

• Elbow Design

• NSF/ANSI 61

• ASME Code

94 Series

Fabricated Y Strainer

• Pipe Design

• NSF/ANSI 61

• ASME Code

93 Series

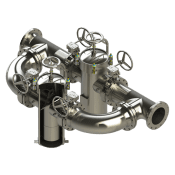

Fabricated Duplex Basket Strainer

• Multiple Configurations

• NSF/ANSI 61

• ASME Code