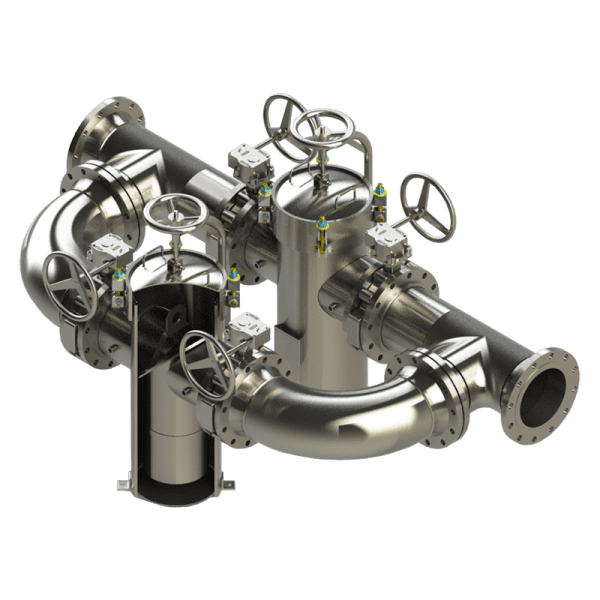

93 Series

Duplex Basket Strainers

93 Series fabricated duplex basket strainers are used in applications where the fluid flow cannot be interrupted when baskets need to be removed for maintenance and/or cleaning. Available in carbon or stainless steel. ASME Code (“U” or “UM”)/Non-Code. sizes from 2″ to 36″.

- Multiple Configurations

- NSF/ANSI 61

- ASME Code

Product Type: Strainer