Challenges in chemical filtration

The chemical industry encompasses a wide range of processes, from synthesis and reaction to separation and purification. Each of these processes generates various types of contaminants, byproducts, and impurities that need to be effectively removed. The challenges in chemical filtration include:

- Chemical Compatibility: Different chemicals may have corrosive, reactive, or abrasive properties, necessitating filtration materials and designs that can withstand these challenges.

- Particle Size: Chemical processes often produce particles of varying sizes, from large agglomerates to sub-micron particles. An effective filtration system must be capable of handling this wide particle size distribution.

- High Temperatures and Pressures: Many chemical processes operate at elevated temperatures and pressures, requiring filtration systems that can withstand extreme conditions without compromising performance.

- Product Purity: Chemical products often need to meet stringent purity standards. Filtration is essential to remove any contaminants that could compromise the quality of the final product.

Tailored Filtration Solutions

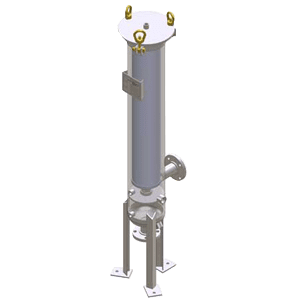

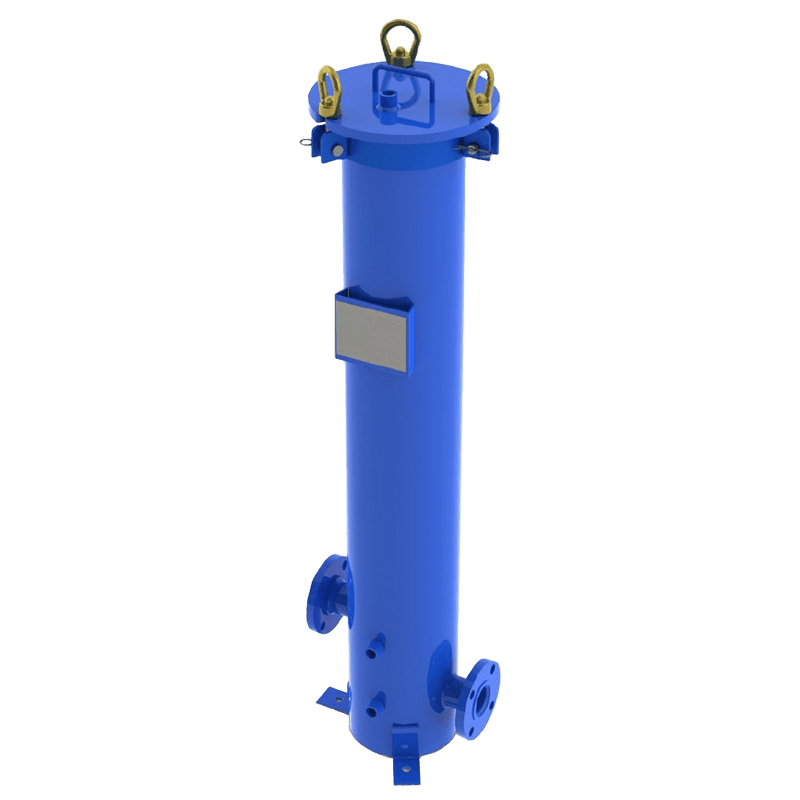

At Fil-Trek, we understand the intricacies of chemical filtration. Our expert team collaborates closely with clients to design and deliver filtration solutions that address specific needs. Our offerings include:

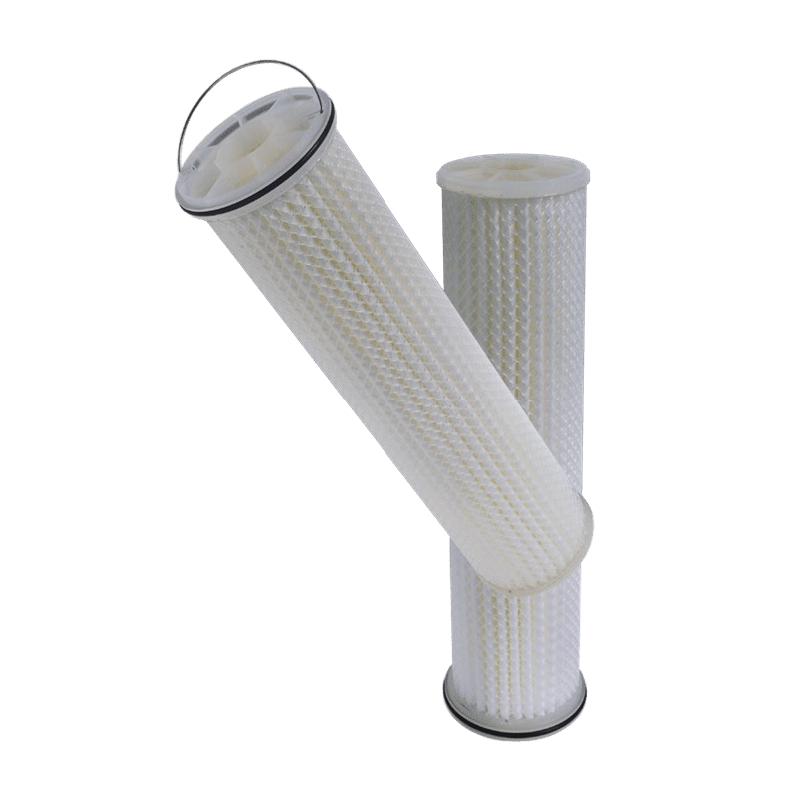

- Filter Media Selection: We help you choose the most suitable filter media, such as woven wire mesh, sintered metal, pleated cartridges, and more, based on your chemical processes and compatibility requirements.

- Custom Filtration Systems: Our engineers design custom filtration systems that integrate seamlessly into your existing chemical processes. These systems optimize filtration efficiency while minimizing maintenance downtime.

- High-Temperature Filtration: We offer specialized high-temperature filtration solutions capable of withstanding extreme temperatures encountered in chemical applications.

- Sanitary Filtration: For industries requiring strict sanitary standards, our sanitary filtration solutions prevent cross-contamination and ensure product integrity.

- Filtration Upgrades: If you have an existing filtration setup, we provide upgrade solutions that enhance performance, extend equipment life, and comply with evolving industry regulations.

Applications

Our industrial filtration solutions cater to a wide range of chemical applications, including:

- Chemical Synthesis: Ensuring the purity of reactants and products during synthesis processes is critical for consistent results.

- Catalyst Recovery: Efficiently recovering and recycling catalysts can significantly reduce operational costs.

- Solvent Filtration: Filtering solvents enhances their quality for reuse, reducing waste and costs.

- Pigment and Dye Production: Filtration is integral in maintaining color consistency and product quality in pigment and dye manufacturing.

- Pharmaceuticals: In pharmaceutical applications, filtration guarantees the purity and safety of medicinal compounds.

Why Choose Fil-Trek

- Expertise: Our team of engineers and filtration experts brings decades of experience in designing filtration solutions for chemical applications.

- Customization: We understand that every chemical process is unique. Our solutions are tailored to your specific requirements.

- Quality: We uphold the highest standards of quality and compliance, ensuring that our filtration systems meet industry regulations.

- Innovation: We stay at the forefront of filtration technology, offering the latest advancements to optimize your processes.

- Collaboration: We consider our clients as partners. We collaborate closely to deliver solutions that drive your success.

Trust Fil-Trek for all your industrial filtration needs in the chemical sector. Contact us today to discuss your requirements and discover how we can enhance your operations through innovative filtration solutions.