Chemical Industry Filtration Solutions

Fil-Trek's Chemical Industry Solutions provide cutting-edge filtration technology that meets the unique demands of the chemical sector. With years of expertise, we offer a diverse range of filtration products to enhance your chemical processes and safeguard production efficiency.

Rental Options Available

Temporary Filtration Solutions

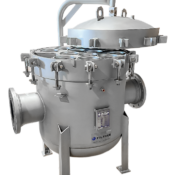

LP Series Housings

Multi-Bag Filter Housing

• ASME Code

• Complies with NSF/ANSI/CAN 61

• Low profile design

TL Series Bag Filter Housing

Single Bag Filter Housing

• ASME Code

• Top in, bottom out configuration

HSL Series

High Pressure Single Bag Housing

▪ ASME Code Rated to 1440 PSI

▪ Compatible with Size 2 Filter Bags

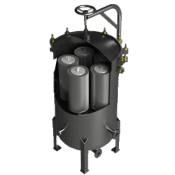

VC Series Carbon Canister Housings

Carbon Canister Housings

• ASME Code

• Vertical Oil Filter Design

700V Series

Multi-Round Cartridge Filter Housing

• ASME Code

• Multi-purpose

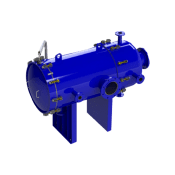

700H Series

Horizontal Multi-Round Cartridge Filter Housing

• ASME Code

• Multi-purpose

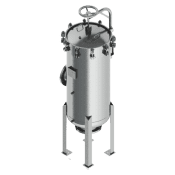

LM Series Housings

Polished Single Cartridge Filter Housing

• Non Code

• Stainless Steel

• Multi-purpose

M Series Housings

High Pressure Single Cartridge Filter Housing

• ASME Code

• Up to 6150 PSIG

HPI Series Housings

High Purity Universal Cartridge Filter Housing

• ASME Code

• Complies with NSF/ANSI/CAN 61

• High Purity & Crevice Free

HT Series Housings

High Temperature Cartridge Filter Housing

• ASME Code

• ANSI Blind Flange Closure

LH Series

Horizontal Lined Cartridge Filter Housing

• ASME Code

• Ideal for corrosive applications

L Series Housings

Lined Cartridge Filter Housing

• ASME Code

• Ideal for corrosive applications

MPH Series Housings

Horizontal Membrane Protection Cartridge Filter Housing

• ASME Code

• Complies with NSF/ANSI/CAN 61

• Ideal for R.O. Prefiltration

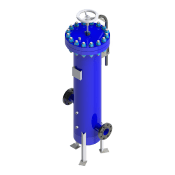

MP Series

Membrane Protection Cartridge Filter Housing

• ASME Code

• Complies with NSF/ANSI/CAN 61

• Ideal for R.O. Prefiltration

FRPH Series Housings

Horizontal Fibreglass Cartridge Filter Housing

• Non Code

• Ideal for corrosive applications

FRP Series Housing

FRP Cartridge Filter Housing

▪ Vinyl-Ester Fibreglass Construction

▪ 100 psi @ 200°F with 4:1 Safety Factor

▪ Accepts DOE Cartridges up to 60″