Power & Utilities Industry Filtration Solutions

Rental Options Available

Temporary Filtration Solutions

Page 1 of 5

PBFC Series

Portable Bag Filter Cart

▪ Mobile, self-contained filtration

▪ Fits P1 or P2 bag filters

▪ Stainless steel 304/316 construction

October 1, 2025

Max Flow Series

Max Flow Multi-Round Vessel

▪ 7.75″ OD jumbo high-flow cartridges

▪ ASME code or non-code options

▪ Up to 2,550 GPM flow capacity

May 26, 2025

DTL Series

Dual Single Bag Filter Housing

• ASME Code

• Top in, bottom out configuration

March 26, 2025

FRP-UFH Series

Fibreglass Reinforced Plastic Ultra Flow Cartridge Filter Housings

- Horizontal Orientation

- Flow rates up to 8,000 GPM

- Industrial Design

February 26, 2025

Fluoro Pure Series

100% pleated Teflon filter

- Polytetrafluoroethylene Membrane

- FDA Title 21 Compliant

- Ratings from 0.05 to 10 Micron

February 13, 2025

TW Series Bags

TW Series Bag Filters

▪ Single Layer Felt Construction

▪ Nominal Ratings from 0.5μm to 200μm

▪ Designed for Fil-Trek TW Series Vessels

January 15, 2025

TW Series

TW Series Dual Format Housing

▪ Accepts TW Bags & 6″ Ultra Flow Cartridges

▪ Horizontal ASME Code Design

▪ Up to 10,000 GPM Flow Capacity

December 12, 2024

Poel Series

Dual gradient polypropylene depth media

• Designed to fit most housing brands

February 7, 2023

Depth Bond

Resin Bonded Cartridge Filter

• Micro-fiberglass/phenolic Resin

• Nominally Rated

• Double Open End

October 30, 2019

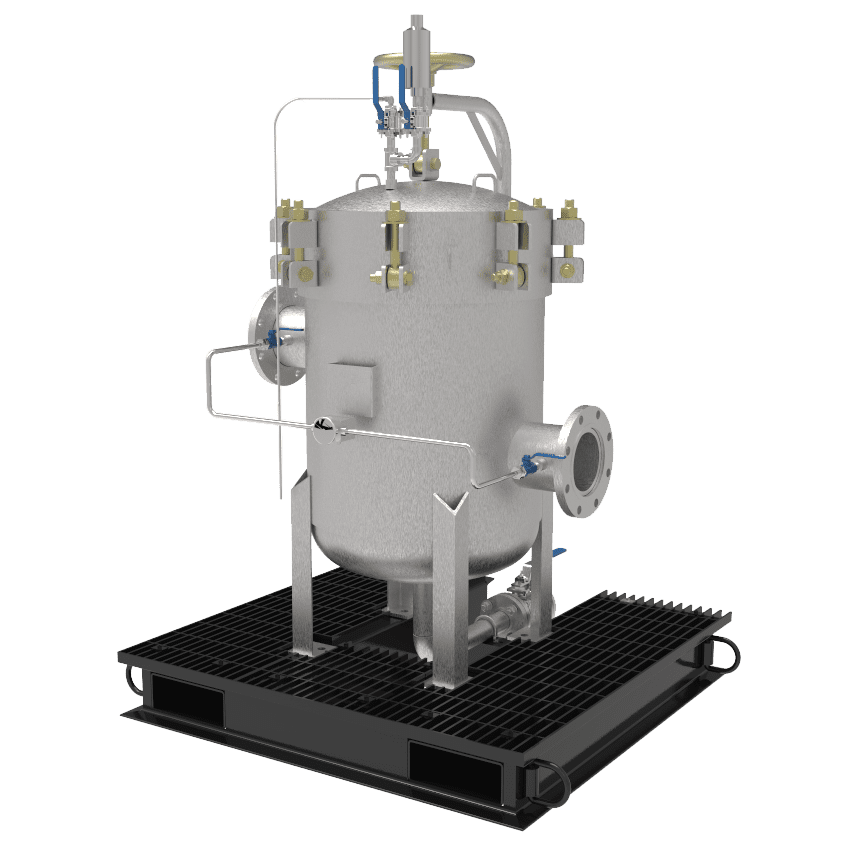

BF Series Multi-Bag Housing

Skid Packaged Bag Housings

• ASME Code

• Ready for immediate start-up

June 20, 2019

Purifier 430 Series

Pleated Cartridge Filter

• 4.25″ OD x 40″ LG

• Absolute Rated

• 226 End Configuration

May 29, 2019

Eco-Mesh Series

Stainless Steel Cartridge Filter

• Stainless Steel

• Pleated or Cylindrical Media

• Cleanable/backwashable

May 9, 2019

Wedge Wire Cartridge Filters

Wedge Wire Stainless Steel Filter

▪ Stainless Steel, 2507 and C-276

▪ High-temp service

▪ Nominally rated

Poroshield Series

Poroshield Sintered Metal Filter

▪ SS316, C-276, or Titanium

▪ Absolute-Rated

▪ 0.5 to 100 micron

Page 1 of 5