Power & Utilities Industry Filtration Solutions

Industrial filtration plays a crucial role in the Power and Utilities sector, where various processes rely on clean and contaminant-free fluids to ensure smooth operations and prevent damage to essential equipment. From power generation plants to utility distribution systems, filtration solutions are employed to remove impurities, pollutants, and contaminants from air, gas, water, and other fluids.

Rental Options Available

Temporary Filtration Solutions

View Rental Skid Fleet

Found 74 Results

Page 5 of 5

Page 5 of 5

Page 5 of 5

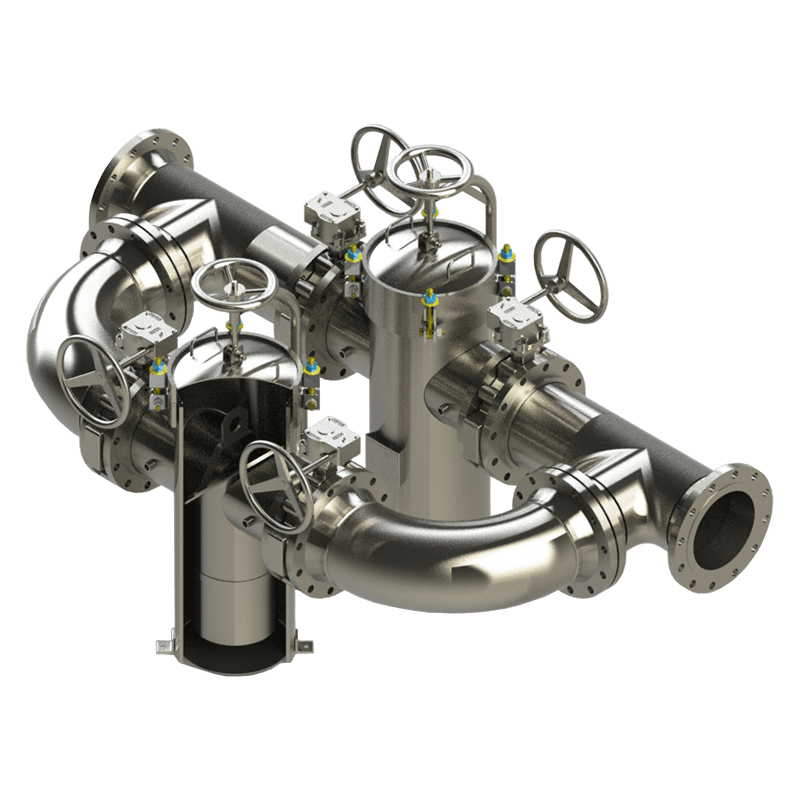

93 Series

Fabricated Duplex Basket Strainer

• Multiple Configurations

• NSF/ANSI 61

• ASME Code

March 7, 2019

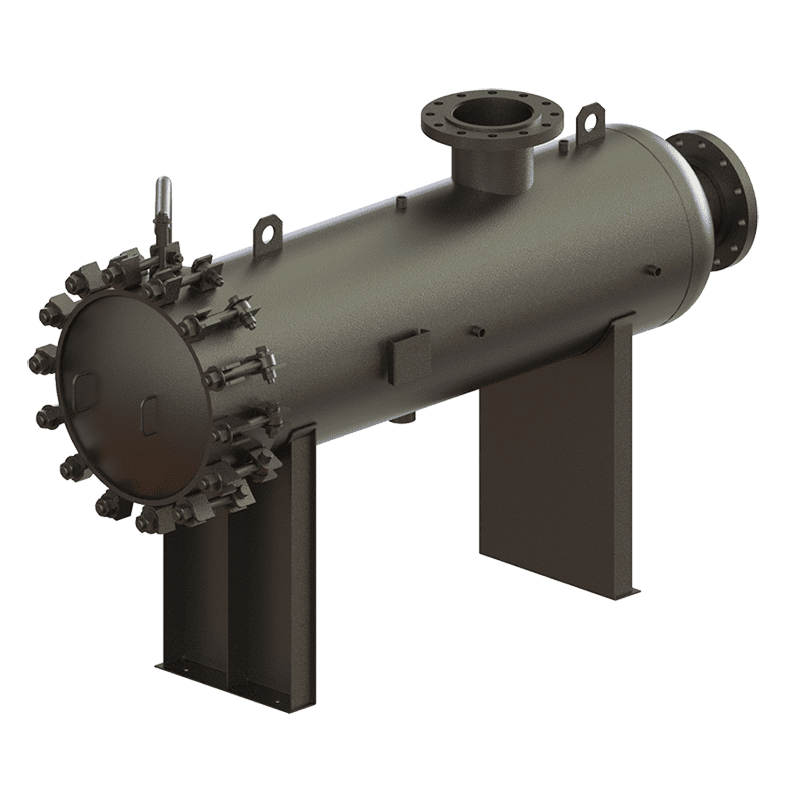

90 Series

Fabricated Basket Strainer

• Inline Design

• Complies with NSF/ANSI/CAN 61

• ASME Code

December 18, 2018

Ultra Flow Series Filter Cartridges

High Flow Cartridge Filter

• 6″ OD, 3″ ID

• Absolute Rated

• Inside to Outside Flow

GL Series

GL Series Multi-Cartridge Filter Housing

▪ Complies with NSF/ANSI/CAN 61 for SS304/316

▪ ASME Code and Non-Code Options

▪ High Flow Capacity – Up to 7500 GPM

Page 5 of 5